Maintenance & Care

Maintenance & Care

Maintaining Your Thermory Project

How do you keep your Thermory project looking and performing its best for decades? Well, that depends on the look you want. Like all real wood, Thermory boards will age and gray over time unless you apply something to delay the process. So the first step is to decide if you’d like to maintain the original brown color, or allow your boards to age naturally.

Natural Brown

The natural result of our modification process is a rich brown color. Maintaining this color on an exterior application requires more time and effort.

Silver

Over time, wood will age to a stunning silver. Allowing your wood to age naturally requires very little maintenance.

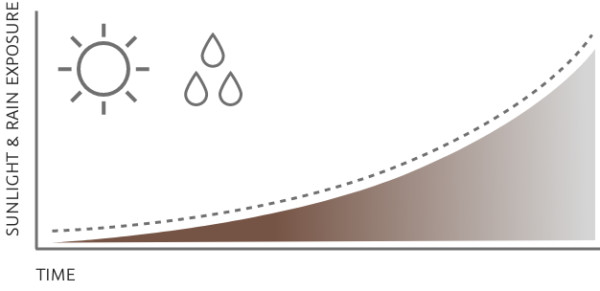

While the brown color is the natural result of our thermal modification process, the silver is a result of wood’s natural aging process through exposure to the elements. UV light and rain both accelerate the aging process – the amount of exposure influences how quickly your project will age. With direct exposure to sunlight, your project may age to silver in as little as 6 months. To preserve the original color outdoors, boards must be maintained with a penetrating protective oil.

Whether you choose to keep the brown or let it silver, your Thermory wood will maintain its core qualities.

ROT RESISTANT

20-25+ years of rot resistance

STABLE

Reduced absorbencyTERMITE RESISTANT

No bugs allowed

SUSTAINABLE

Responsibly harvested and chemical free

SMOOTH KISSED

Milling so smooth you’ll have to touch it to believe itHow To Maintain Your Thermory Product

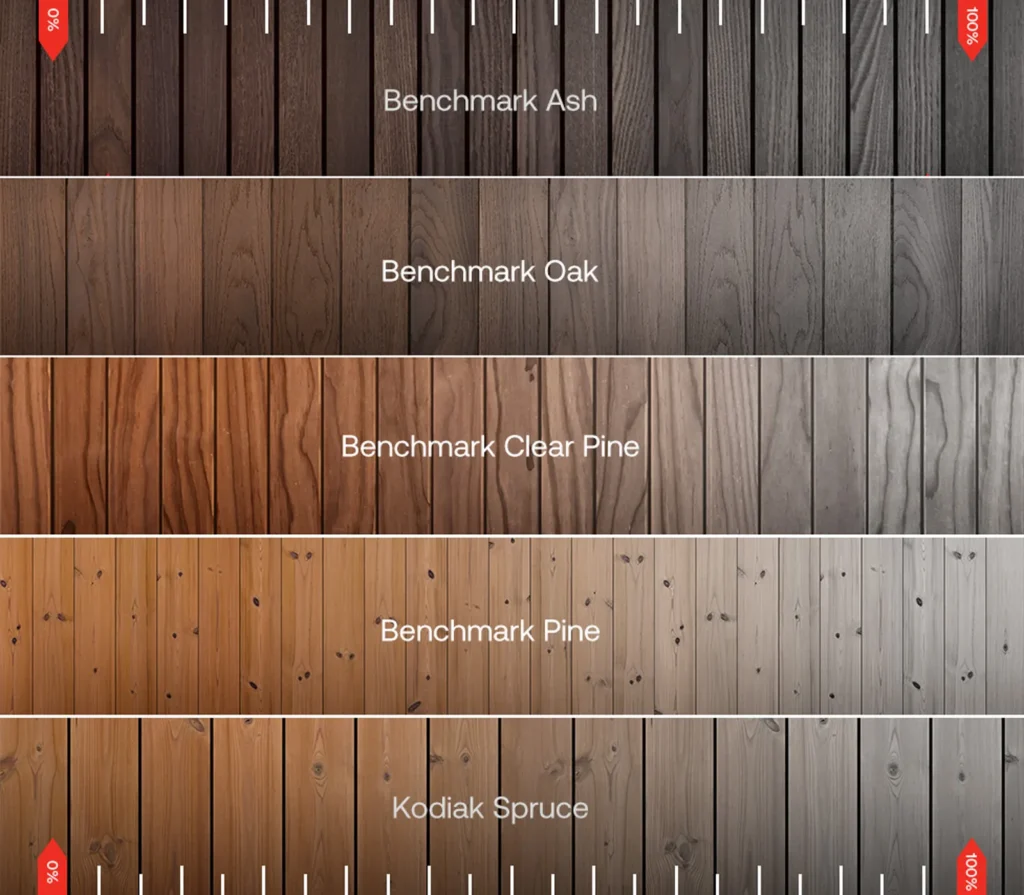

For exterior projects, your maintenance requirements and routine differ based on your desired outcome and the Thermory product you choose. Our finished product line Ignite, has different maintenance needs than our natural Benchmark or Kodiak product lines. Though the maintenance may vary, the performance of our boards does not. That means there are no wrong choices – just decades of rot resistance and stability with the look of your choice.

Maintaining Natural Brown (All Species)

- Prefinish prior to installing.* This step is critical to slow the aging process on all sides of the wood. Prefinishing should be done with a penetrating UV protectant oil.

* Thermory strongly recommends factory finishing to protect all sides of the wood. Results may vary if protection is applied after installation.

- Depending on exposure to direct sunlight, to exposed surfaces after 1 year or per manufacturer’s directions. For projects with more direct sun exposure, reapplication may be required sooner.

- Follow the instructions provided by oil manufacturer for application.

- Sand the surface of the deck before 1st application

(Almost) No Maintenance Required

Allowing your Thermory wood to naturally age to a stunning silver is your easiest option when it comes to maintenance – and it won’t impact the longevity or stability of your project at all!

- Prefinish prior to installing. This step, though not required, is critical to allowing the wood to age evenly and prevent checking. Prefinishing should be done with a penetrating oil with UV protectant.

- Keep your deck clean. Yeah – that’s really it. Enjoy your 25+ years!

Maintain With Periodic Repainting

The bold look of Ignite does require some repainting to stay fresh outdoors. The paint has been tested to last 5 years. For Dragon Scale products, the texture is embossed into the surface of the board, therefore the texture will not require refinishing.

- Repaint as needed. Color matches are available through Benjamin Moore.

- For small scale touch ups, we recommend using Teknos Woodex stain.

- For Dragon Scale projects, we recommend reapplying the paint with an airbrush system.

Maintain With Periodic Reapplication

- Clean well with lukewarm water and neutral detergents (e.g., water and neutral dishwashing liquid) using a soft cloth. When removing traces of dirt or grease, use the neutral detergent RR1050 (Renner Italia) and a microfiber cloth. We recommend conducting the cleaning every 3-6 months, depending on local conditions.

- After cleaning, refinish as needed, according to your chosen Vivid color and the exposure conditions of the surface.

- In very exposed areas subject to discoloration: apply one coat of the previously applied Vivid color by brush.

- In little exposed areas in good condition: apply a coat of a blend of 2 parts of uncolored and 1 part of the previously applied Vivid color by brush, to renew without changing the final color over time.

- We recommend avoiding spot-painting, and instead repainting the whole wall or section at once.

- For textured boards, we recommend reapplying the paint with an airbrush system.

Wish It Was Still Brown? No Problem!

If you allowed your wood to age to silver and miss the original color, getting it back may be easier than you think!

- Clean the surface with a wood brightening cleaner.

- A stiff-bristled brush is your best choice.

- If you prefer power washing, use the lowest setting and the widest fan.

- Wait 1 day before oil application.

- Apply a UV protectant oil according to manufacturer’s directions

- That’s it! Re-oil annually or as needed to maintain color, as described above.

For Long-Term Performance, We Recommend Factory Finishing

Whether you choose to maintain the original brown or allow your wood to age to silver, Thermory always recommends factory finishing prior to installation. We’ve partnered with our distributors to ensure every order can be factory finished before being shipped to our customers. There are a couple reasons we always recommend this critical step.

Protection On All Sides

Flood-system finishing allows for all 6 sides of every board to be thoroughly coated in your finish. While the surface sides may require ongoing maintenance, an initial coating of oil is enough to protect ground- or inside-facing surfaces from trapped moisture for the lifetime of your project.

Consistent Color

An initial coating of oil allows the wood to age evenly – whether you’re planning to maintain the original color or allow it to silver. We recommend a penetrating oil in part for this very reason – by conditioning the wood beyond the surface, it will all age at the same pace.

Smooth-Surface Maintenance

Factory finishing with a penetrating oil also helps reduce checking and shaking over time. By conditioning the wood with a penetrating oil, small imperfections that often occur over time are prevented. We’re proud of our Smooth Kissed Milling texture – factory finishing allows it to last even longer.

Factory Finishing

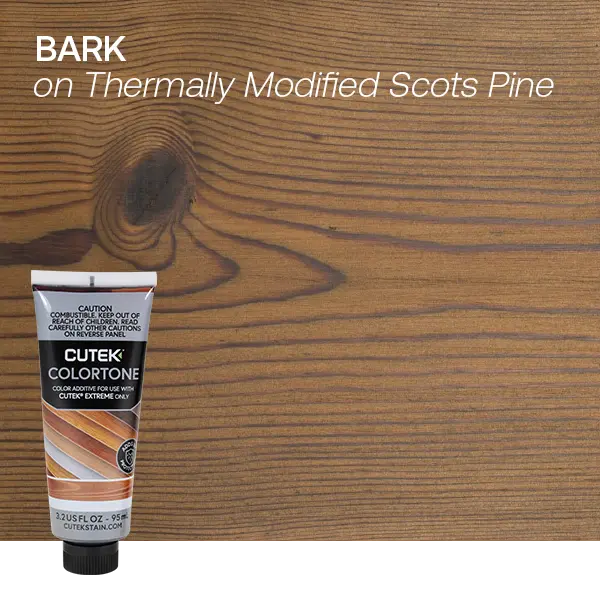

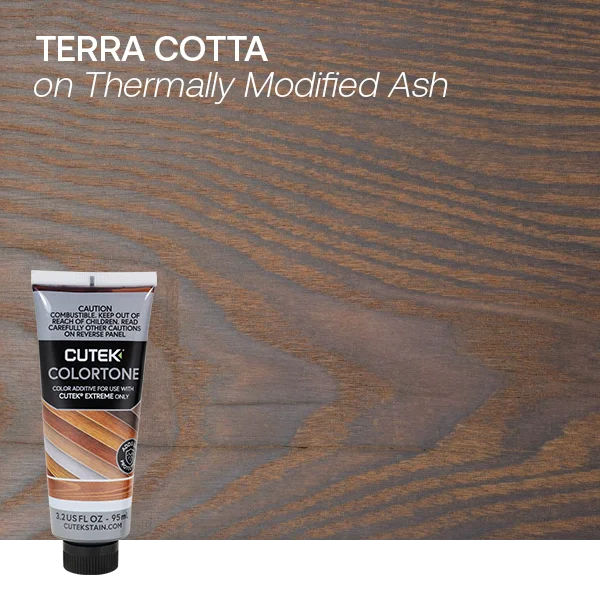

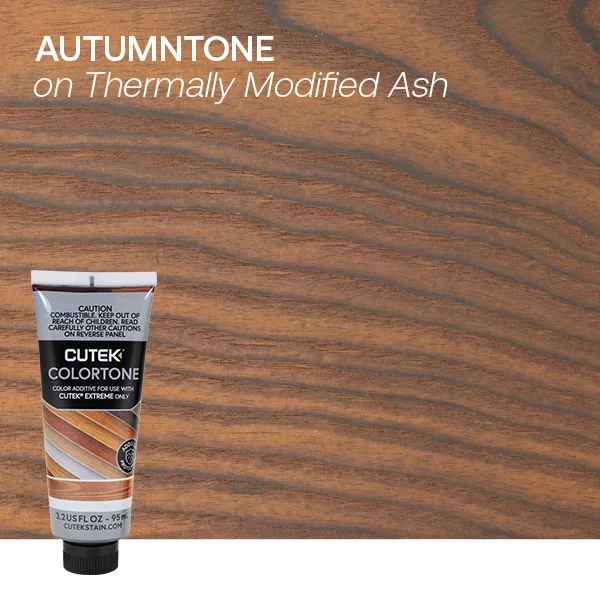

Keep your wood’s natural tone looking fresh with our recommended UV protective oil. Have it finished before it’s shipped to save yourself the extra step.

Want to talk it out?

We recommend factory finishing so strongly that we’ve partnered with our distributors to make sure it’s available on every Thermory order. To learn more about the finishing options available to you and to get recommendations on how to best protect, enhance, or add color to your boards, call us—we’re happy to help!