When our product specialists visit an architectural CEU, showroom, or jobsite with Thermory samples, they’ll often hear the same question:

“Which ones are real wood?”

As Cristian de Rosa (Thermory Building Product Specialist) puts it, the answer is always the same: “All of them.”

Yet even experienced architects and designers are often surprised to learn that Thermory is real, solid wood.

De Rosa explains: “Clients will often tell me that they want real wood, but don’t want to maintain it. People truly want real wood at their core. This is why there are countless companies spending millions to make plastic look like wood.”

The good news? Thermory products are real, natural wood, enhanced through a specialized heat and steam process called thermal modification, pioneered by our company in the 1990s.

No chemicals. No fillers. No synthetic materials.

This blog dispels the common myths we hear about our thermally modified wood.

Myth #1: Thermory Isn’t Real Wood

Fact: Thermory is 100% Real wood.

Thermory starts with sustainably sourced hardwoods and softwoods—species like ash, pine, spruce, and more. The boards you see on projects are solid wood boards, not composites or veneers.

De Rosa sums up a common misconception he hears from architects and specifiers:

“Usually, the challenge I have is getting people over the hump that this is a real, natural wood product that no longer requires extensive maintenance to live a full life. People look at our beautiful material and assume it’s been stained, treated—you name it. They can’t wrap their head around the fact that the formula is just heat + steam + wood.”

Our team member who covers projects in the Midwest, Danny Kent, hears a similar concern:

“I usually hear ‘real wood doesn’t do well in our area.’ I explain that if builders install the material properly (according to our installation guidelines), they can get 20 to 25+ years of no cupping, crowning, rot, or decay.”

Myth #2: Thermory Is Chemically Treated

Fact: Thermal modification uses only heat and steam—no chemicals.

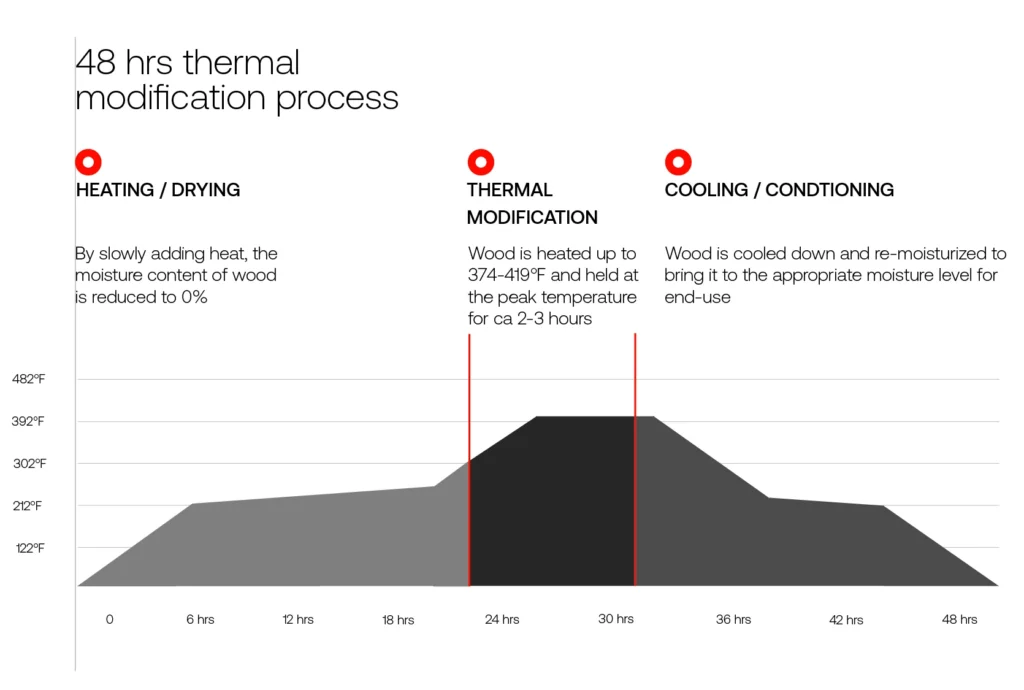

Traditional treated lumber relies on chemical preservatives to improve durability. Thermory takes a different approach. The wood is placed in specialized, retrofitted kilns and heated to high temperatures in a low-oxygen environment, with steam used to control the process. Our wood scientists have refined this process over 25 years. This changes the wood’s internal structure, making it more stable, resistant to decay, and less prone to movement without adding anything to the wood.

Steve Butler, Thermory’s Pacific Northwest Product Specialist, notes:

“We’ve done such a good job conveying our benefits, like dimensional stability and low maintenance, that customers start viewing us like a composite material. Stressing that we are refining a natural product—not creating one—is increasingly important.”

Myth #3: All Thermal Modification Is Equal

Fact: Not quite.

Our proprietary thermal modification process permanently changes the wood’s cell structure by removing moisture and sugars that attract decay and insects. This reduces the wood’s ability to absorb water, which is one of the main causes of rot, warping, and swelling.

The result is wood that is:

- More dimensionally stable

- More resistant to decay and insects

- Lower in equilibrium moisture content

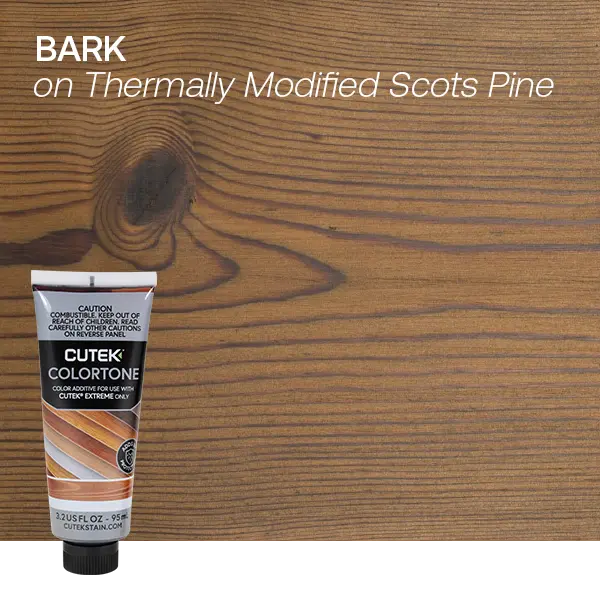

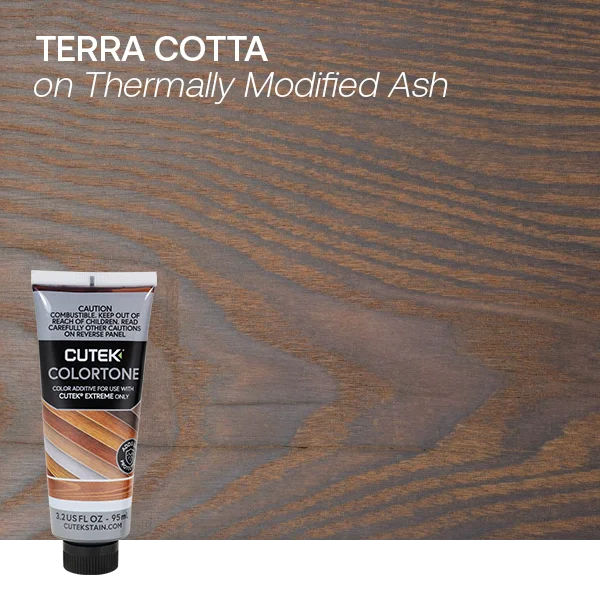

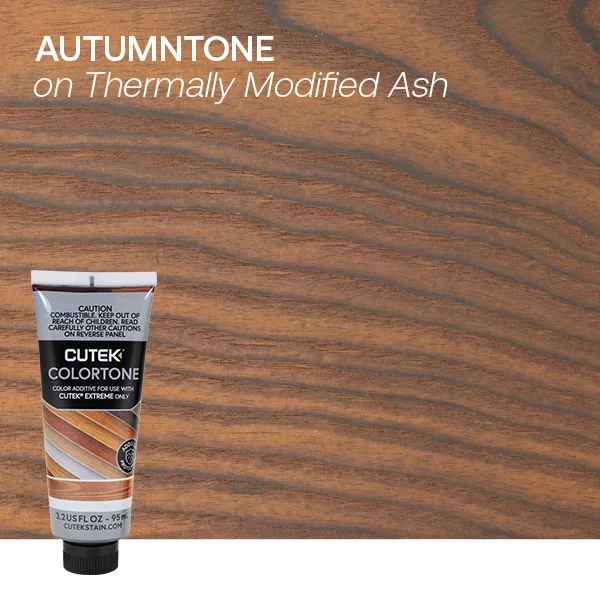

- Rich in color throughout the board

De Rosa’s go-to explanation:

“We utilize heat to pull out all of the organic matter from the wood, while introducing steam into the mix to maintain temperature control and keep the moisture content at a level that maintains stability and durability in the board.”

Kent adds a technical analogy:

“We use very high heat—over 400 degrees—to cook out the sugars and other food sources that attract rot-causing insects. It also solidifies the lignin polymers that act like rebar in the wood, keeping it durable and stable.”

At Thermory, we’ve been perfecting our process for over 25 years—outlasting our warranty period—with a team of wood scientists and engineers. Today, we are the world’s largest producer of thermally modified wood and sauna materials, exporting to 60+ countries.

Our state-of-the-art thermokilns are custom-retrofitted to meet strict Thermory standards, ensuring precision and consistency in every thermal cycle.

Why Thermal Modification Matters

Because the process changes the wood at a molecular level, the benefits are built into the board instead of applied on the surface.

Butler explains, “We take furniture-quality wood species you’d never dream of using outside, and through a proprietary heat and steam process, modify them so we can warranty them against rot and decay for at least 20 years. The modification happens down to the cellular level, and it’s a completely natural process developed over nearly thirty years.”

Designers, builders, and homeowners choose Thermory for the beauty of real wood—with enhanced performance for demanding environments.

Real Wood. Real Performance. Real Sustainability.

Thermory isn’t composite.

It isn’t pressure-treated lumber.

And it isn’t coated with chemicals.

It’s real wood, enhanced by nature-inspired technology—heat, steam, and time—to perform better in modern architectural applications.

Butler puts it simply:

“Thermory is natural. No off-gassing, no environmental reactions of caustic chemicals. Our real wood provides warmth, natural sound attenuation, and a connection to the natural world you can’t get from engineered or composite materials.”

Choose real, durable wood. Choose Thermory.

Photo Credits: Marita Mones. Tõnu Tunnel